25% Tariffs on Parts: How Shops Can Prepare

Analyse Trump’s proposed tariffs on imported car parts, cost impact on repairs, and strategies to protect your margins.

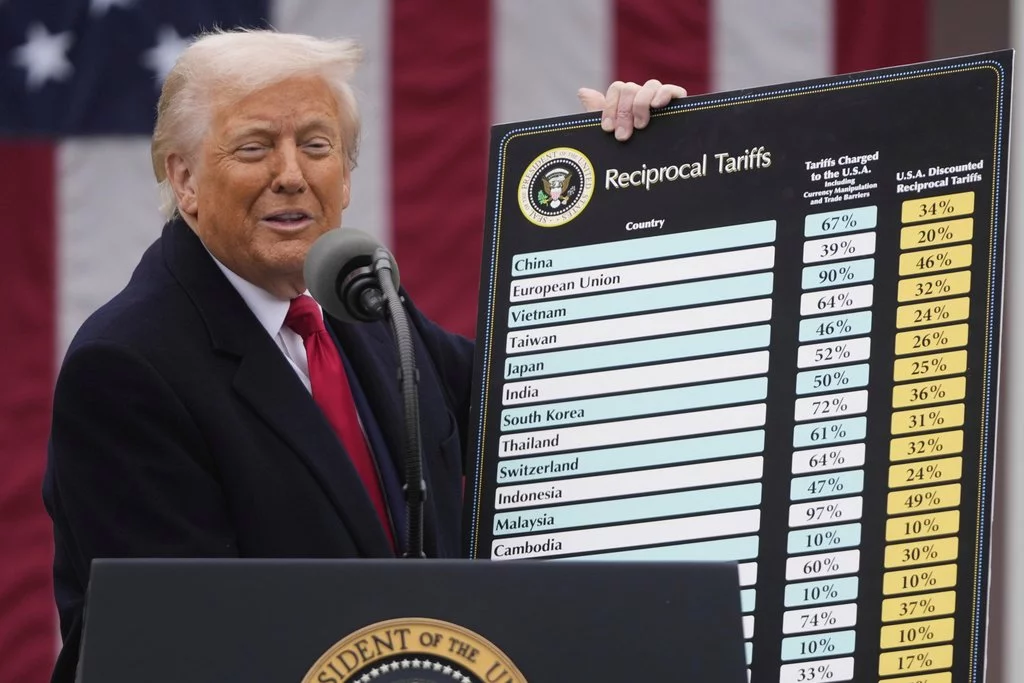

As trade policy debates continue to simmer, one idea keeps grabbing headlines: a proposed 25% tariff on all foreign-made cars and car parts, championed by former President Donald Trump. For the average driver, this might sound like a distant jab at global automakers. But zoom in, and the real impact could hit much closer to home—right in the bays of independent auto repair shops and garages across the country.

What’s Behind the Tariff Talk?

The plan would slap a 25% tax on every imported vehicle and component entering the U.S. That means everything from brake pads and alternators to sensors and timing belts—parts that independent repair shops depend on daily. The pitch? Supercharge American manufacturing and reduce reliance on overseas production. The problem? For small businesses like local garages, the immediate fallout could be a costly, disruptive mess.

How This Could Shake Up Auto Repair Shops

Here’s how these tariffs could put the squeeze on the shops that keep your car running:

- Soaring Part Costs A 25% tariff translates to a 25% price jump on imported parts—plain and simple. Since foreign components are used in both imported and American-made vehicles, shops can’t just switch to “domestic only” to sidestep the hit. From spark plugs to radiators, higher costs could become unavoidable.

- Supply Chain Snags Tariffs don’t just inflate prices—they throw supply chains into disarray. Suppliers might struggle to keep parts in stock as they scramble for new sources or renegotiate global deals. For shops, that could mean longer waits for critical components, delayed repairs, and customers left fuming.

- Profit Margins on the Brink Independent garages already run on tight budgets. With part prices climbing, passing those costs to customers risks driving them to competitors—or worse, delaying repairs altogether. It’s a no-win scenario: hike rates and lose business, or absorb the costs and watch profits evaporate.

- Small Shops vs. Corporate Giants Big dealership service centers often have the cash flow and supplier clout to weather price spikes. But smaller, family-run shops? They’re in a tougher spot, with less bargaining power to secure deals or cushion the blow.

How Shops Can Get Ahead

While the tariffs remain a proposal, savvy shop owners aren’t sitting idle. Here’s how they can prepare for what’s next:

- Branch Out to New Suppliers: Start sourcing from domestic or regional vendors to lessen the import hit.

- Stock Up Strategically: Build reserves of high-use parts before any price surges kick in.

- Plan for Price Hikes: Craft a game plan to explain cost increases to customers without breaking their trust.

- Stay Informed: Keep tabs on trade policy updates and industry trends to pivot quickly if the tariffs move forward.

Why This Matters Now

This isn’t just a Washington talking point—it’s a real challenge staring down thousands of small businesses that keep America’s wheels turning. From pricier repairs to longer wait times, a tariff hike could ripple through one of the nation’s most essential service industries. For drivers, it might mean digging deeper into their wallets. For the shop down the street, it could be a battle to stay in business.

What’s your take—would these tariffs boost U.S. jobs, or just slam small businesses?

Ready to Transform Your Workshop Operations?

Join 1000+ successful auto workshops using autoGMS to streamline operations, reduce no-shows, and boost revenue.

Related Articles

Continue reading with these related posts